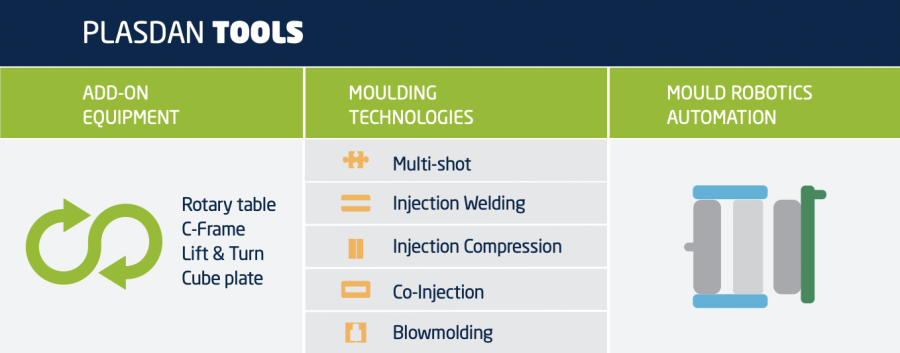

Plasdan USA offers efficient and innovative "Add-On" and "In Mold Assembly" Systems for the injection molding industry with a mission to improve our customer’s profitability. Give us a call or send us an email to learn more about our modular injection units, rotating platens and in-mold assembly systems.

View Plasdan Technical Brochure

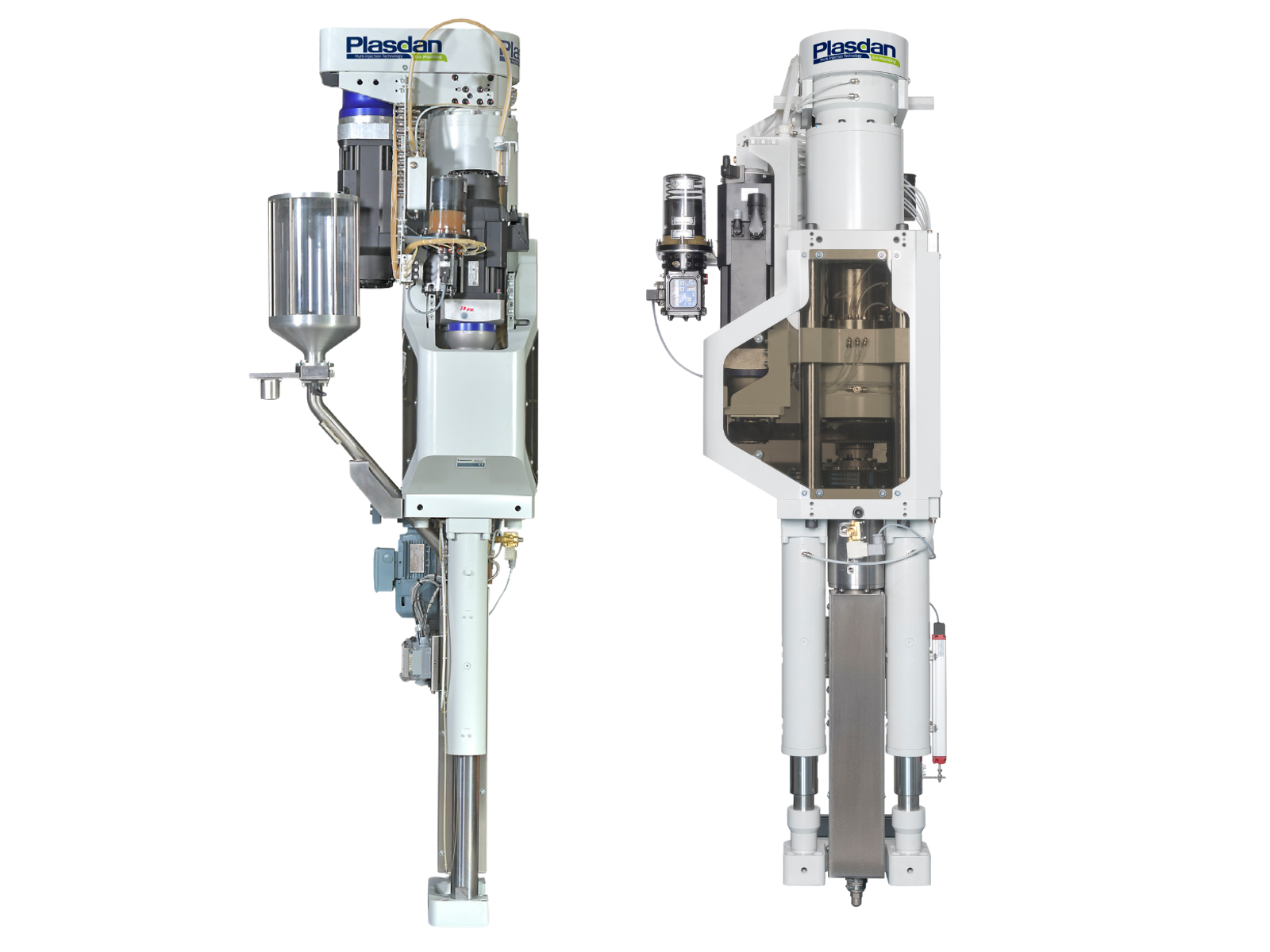

Add-On Injection Unit: Ergoline Series

Add-On Injection Unit: Hi-Per Series

Micro Add-On Unit: 2-Stage Injection

Evolve your standard injection molding machine into a multi-shot capable machine.

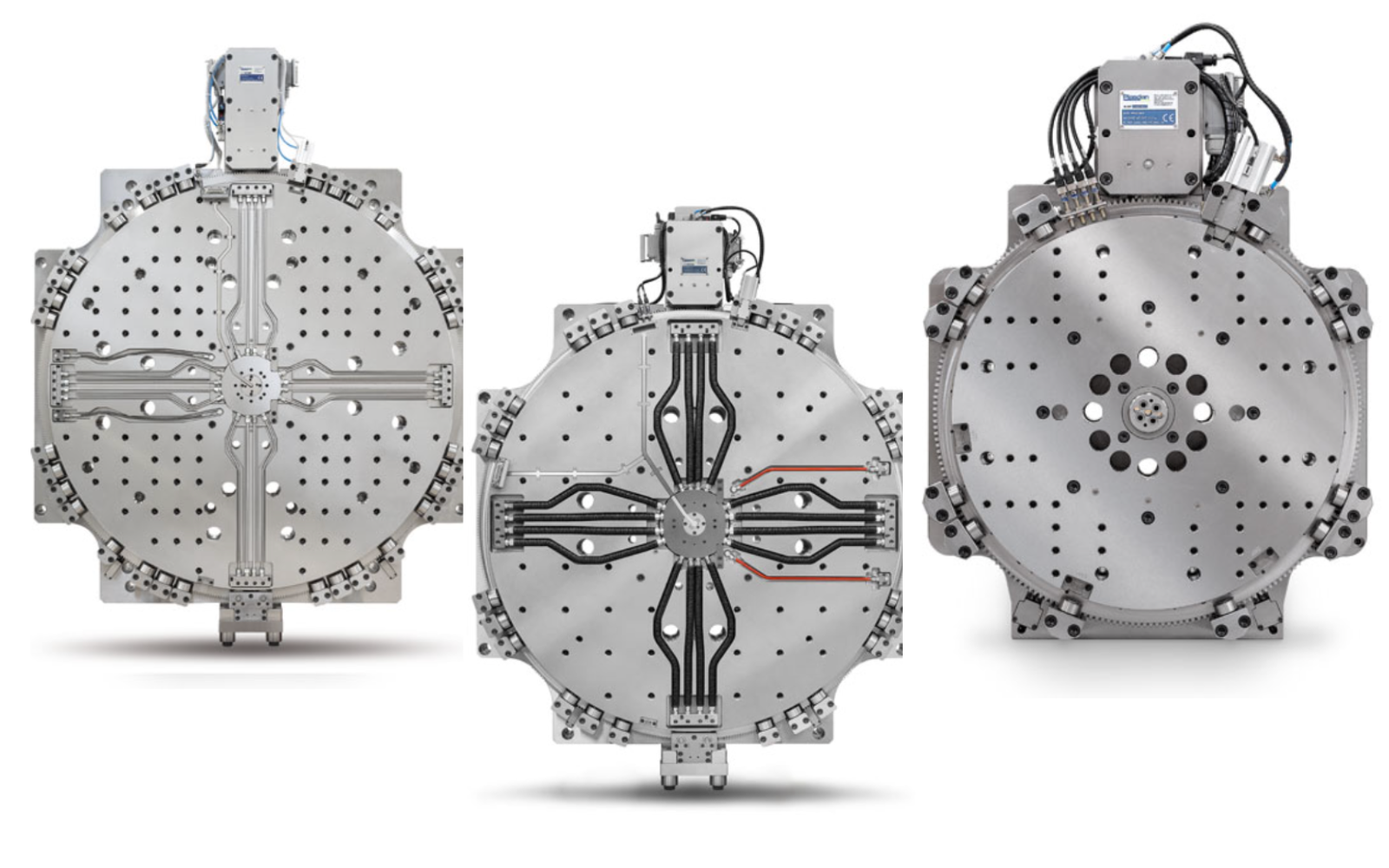

The full electric rotary table is a positioning device, fixed to the machine platen. It is equipped with an electric servomotor for fast and precise rotation and positioning of the respective mould half. When supplied with other addons from Plasdan it will share the same PLC and controller for ease of application and extremely user friendly.

High-tech industries, such as medical, electronics and packaging, are increasing the complexity of parts requiring multi component solutions; add-on injection units are the perfect answer to provide these solutions.

Our mission is to enable our customers, in particular, and the injection moulding industry, in general, to be profitable, efficient and sustainable.

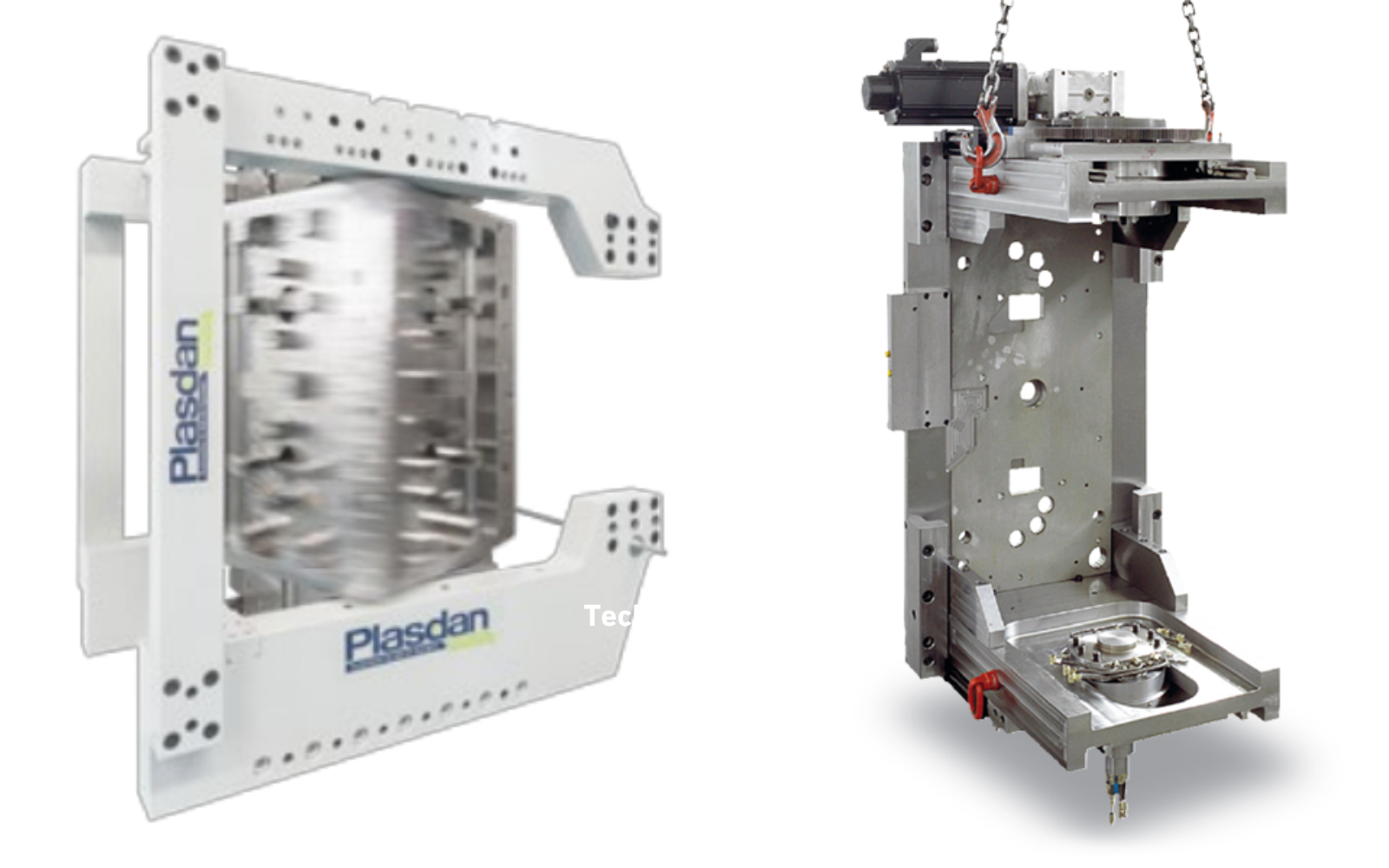

The C-Frame construction often enables the relocation of the system to another compatible press/IMM.

The C- Frame is a support system for a rotary cube mould that allows the central block of the cube to rotate through either 90º or 180º depending on requirements, transferring the previously injected parts from one processing station to another.

1) Increase the production capacity of existing machines.

2) Install new features on existing molding machines.

3) Production cells.

4) Enable flexible and competitive operation in a global market environment.

5) Innovative automation and mold robotics. (Assembly cost reduction)

6) Innovative molding technologies.

7) Efficient logistics process

8) Environmental friendly (energy savings).