ZAG Consulting Services strives to improve our customers’ profitability by solving today’s challenging manufacturing headaches. Our team of plastics professionals, with decades of experience in all facets of plastics manufacturing – training, mold design, equipment and resin selection, process improvement, manufacturing support, and more – delivers solutions resulting in measurable production and process improvements.

From training process technicians to solving complex organizational challenges, ZAG Consulting Services offers industry expertise helping our customers achieve their goals.

Process Improvement

• Machine Selection

• Material Handling Instruction

• Mold Set Up Instruction

• Process Improvement

• Cycle Time Reduction

• Instrumented Molding Implementation

• Machine Testing and Assessment

Manufacturing Support

• Project Management

• Manufacturing Cell Layout

• Lean Manufacturing

• 5S Methodology

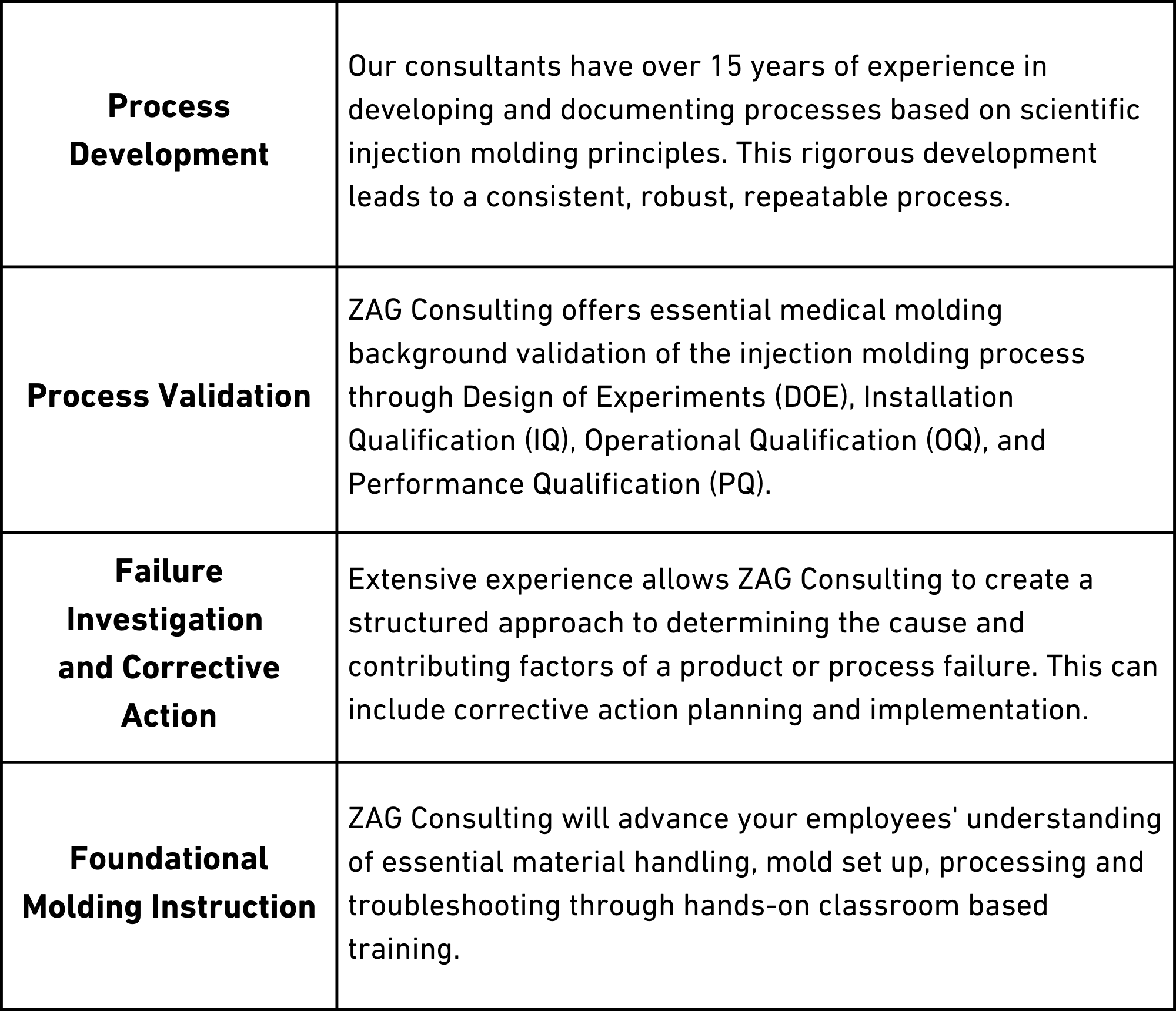

• Failure Investigation

• Corrective Action

Validation

• Validation

• Tool Launch

• Tool transfer

• Process Development

• Design of Experiments (DOE)

• Qualifications - 1Q, OQ, PQ

• Train Process Tech

• Reduce Cycle Times

• Process Development & Mold Acceptance

• Improve Part Quality

With over 20 years of injection molding, consulting and training experience, Marty Key helps customers improve molding operations and profitability. Offering a range of consulting services, Marty delivers proven solutions from eliminating processing headaches to solving organizational challenges.

Marty's extensive expertise and unique technical skills result in measurable manufacturing improvements.

• Training

• Part Validation

• Mold/Plant Design Review

• Process Improvement

• Manufacturing Support

• Quality Systems

'Injection Molding Process Training' Classes held here at ZAG Equipment Sales by our Industry Expert, Marty Key.

This three day class includes both a hands-on and classroom learning experience, and will prepare you for a career in Injection Molding. Contact us to secure your seat for the next class! All classes held at our facility: 1239 Springwood Church Road, Gibsonville, NC 27249

View Injection Molding Elements Class Outline - Introductory Class

View Principle Concepts of Injection Molding Class Outline - Intermediate Class