Retrofit your existing flow regulators with Flosense today. At last you can see real flow measurements at a glance, and use the alarm limits (and output) on flow and temperature to control the process stability and part quality.

"We ran two shifts of production only to realize the TCU was connected backwards. It was turned on, but no water was going through the mold. Our Flosense manifold now alarms on the machine controller when there is a problem."

-Current Flosense customer

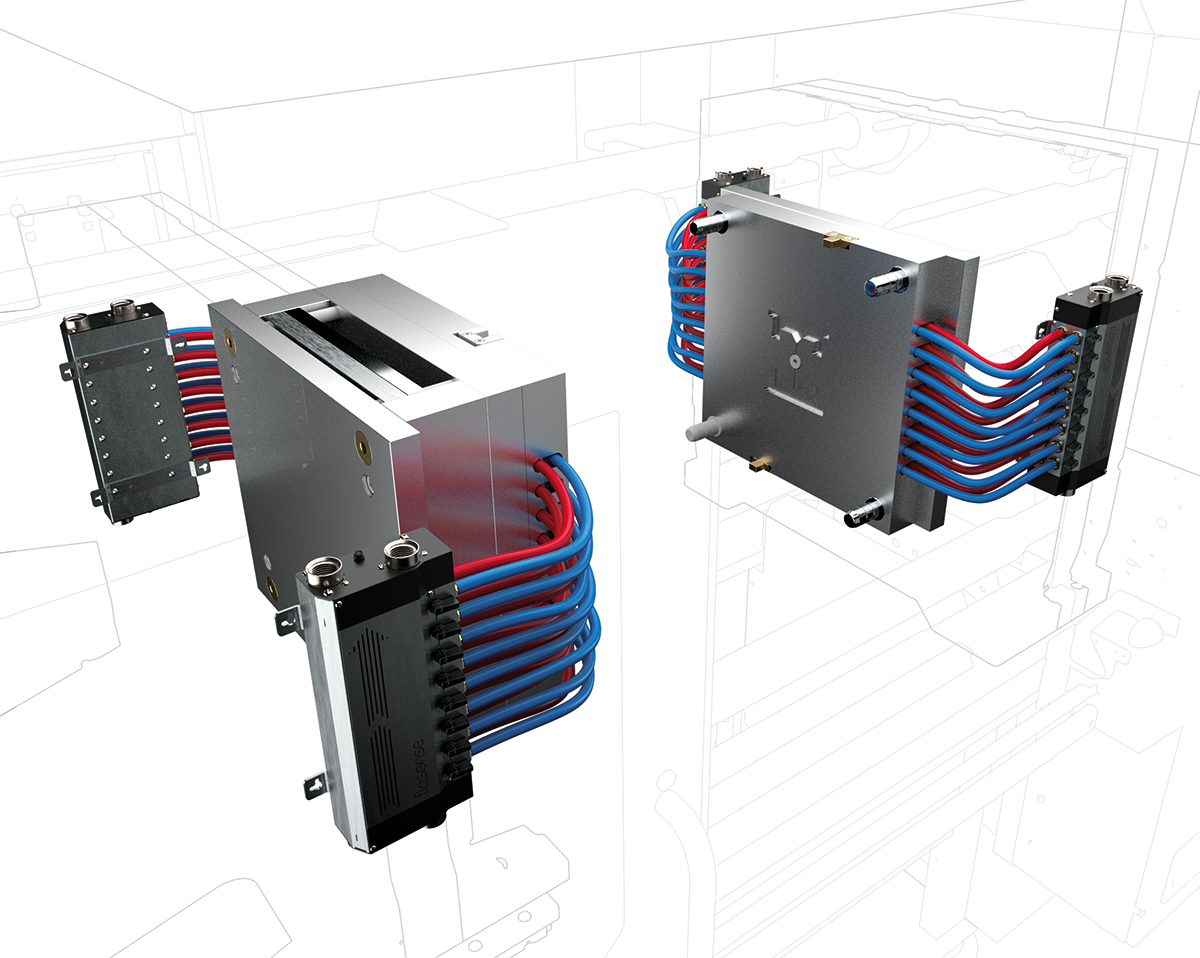

Replacing traditional analogue manual flow regulators with new digital flow regulator will give you many advantages such as:

•Digital monitoring of Flow, Temperature and Pressure

•Alarm Output

•Higher flow capacity

•Higher temperature range

•Data storage and export

•Faster Mold changeovers

•OPC-UA / Euromap interface /

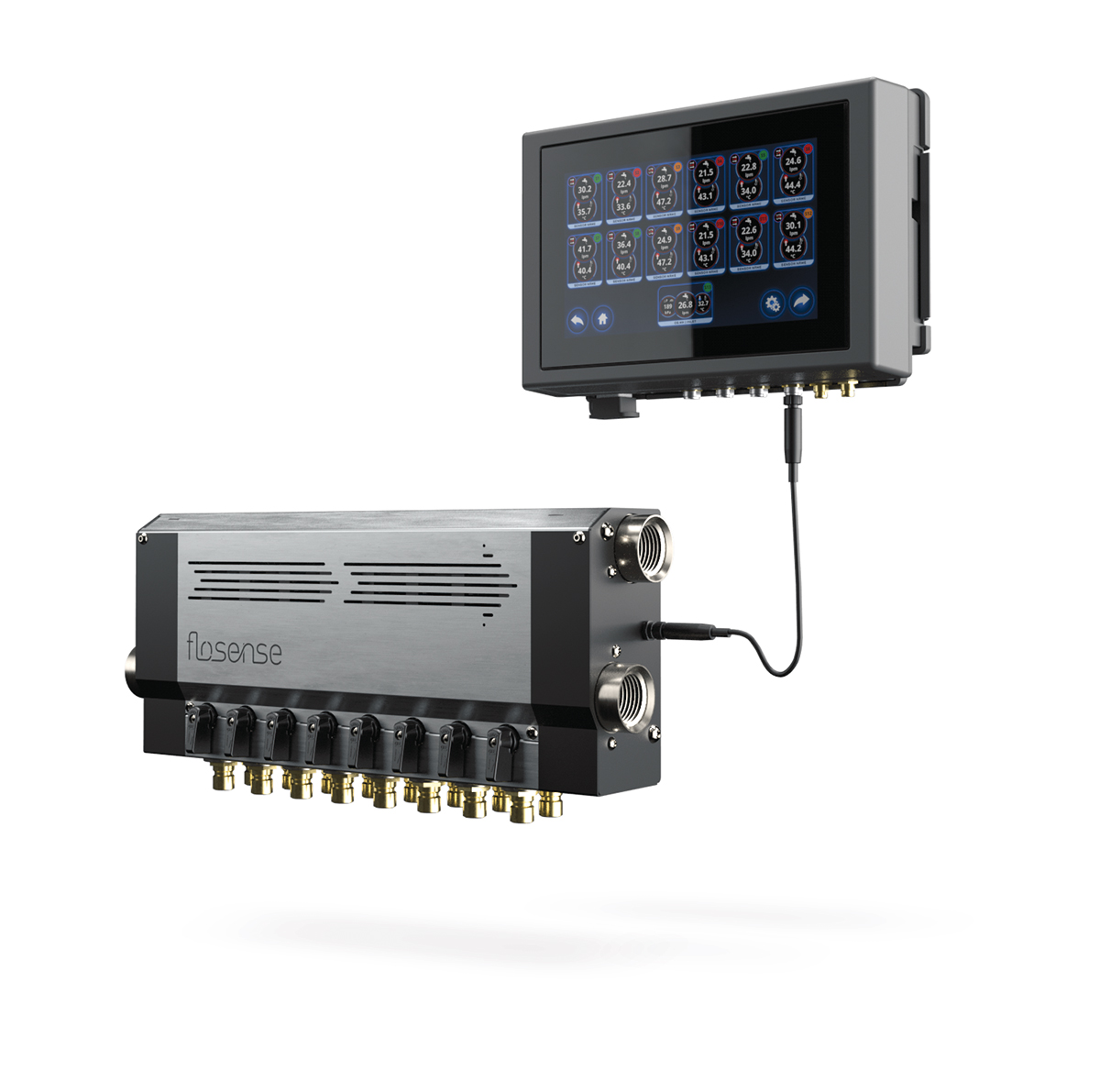

Touch screen with 4 manifold inputs. With magnetic bracket for easy installation. Equipped with power, alarm, USB and Ethernet connections.

•The main screen will show all circuits with information about flow and temperature. The main inlet and outlet will also show including pressure.

•Data is stored in the internal memory and can be displayed in graphical view for each circuit. Data can also be exported for external use.

•By clicking on a specific circuit you will see detailed information, including delta T (heat transfer) of the specific channel. Also, turbulent flow indicator is included.

•The system is equipped with Audit Log to keep track of all events including user ID tracer.

Connect up to 4 manifolds to the touch screen in order to monitor up to 48 separate cooling circuits.

Use the alarm limits (and output) on flow and temperature to control the process stability and part quality.